smd led diode

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | smd led diode |

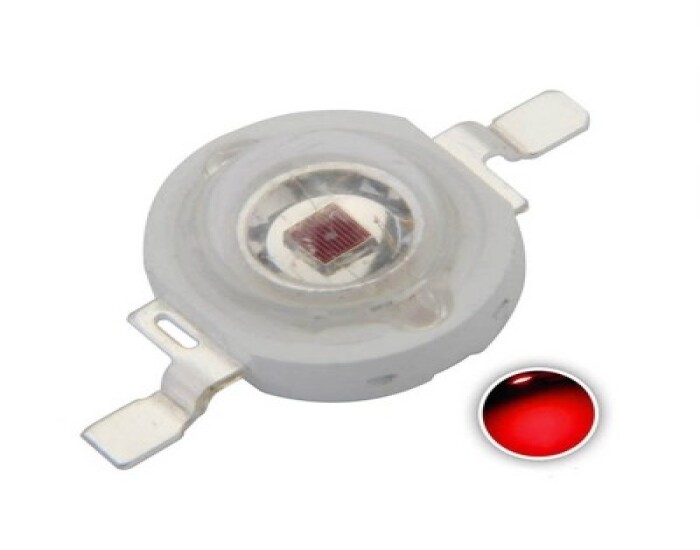

| Keyword | smd led for keyboard,lechat integlow smd led lamp,2 pin smd led,3w high power deep red 640-660nm smd led,china smd led manufacturers |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 131MA |

| Power | 1.7W |

| Voltage | 2.7V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2667pcs/reel |

| Dimensions | 4.4mm*5.5mm*2.7mm, (Contact us for specific information to confirm) |

| Applicable Industries | energy-saving lighting, etc. |

| Color | purple |

| Weight | 14mg |

| Product Description | 4014 smd led datasheet,0402 smd led white,5 smd led 5050-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 53307 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 18x10.31x14.3mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Gabon,Denmark,Iceland,North Korea,France |

| MOQ | 7 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 91kk pieces of LEDs per month. |

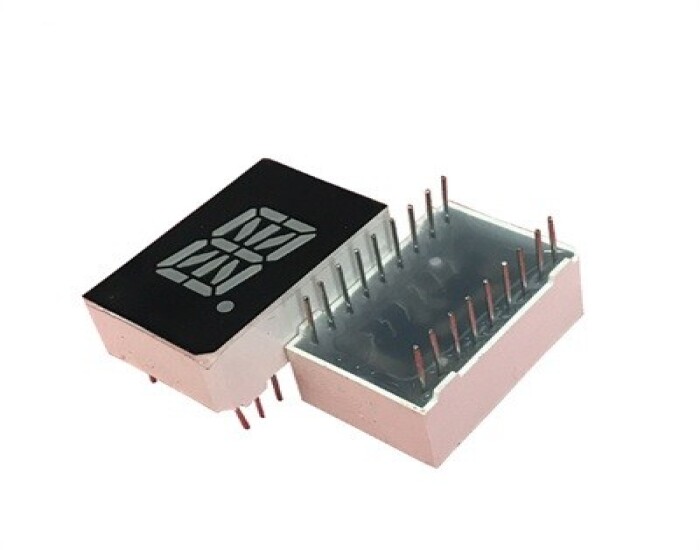

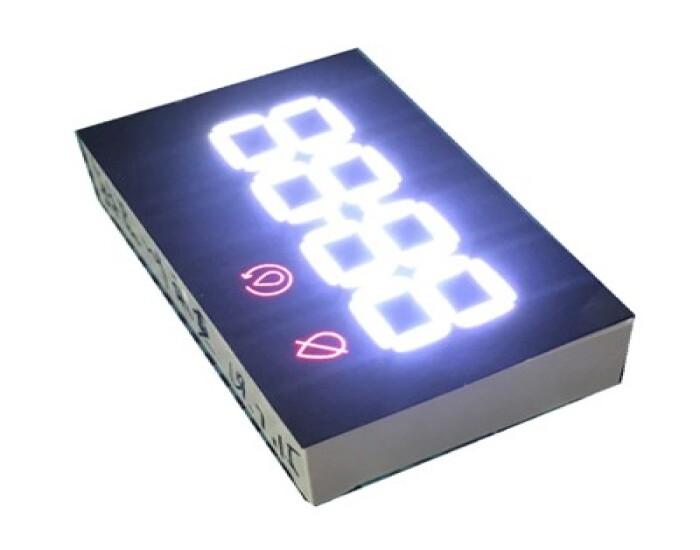

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

smd led diode services FAQs Guide

Are you looking for a quick review guide about smd led diodeservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding smd led diode services.

Let’s continue!

2.Are smd led diodes energy efficient?

3.How does the color temperature of smd led diode affect its use?

4.What is the typical power consumption of smd led diode?

5.What is the installation process for smd led diode?

6.About smd led diode quality system

7.How does smd led diode hold up against extreme weather conditions?

8.What is the warranty period for smd led diode?

9.Are there any environmental considerations when using smd led diode?

10.About the scale of smd led diode factory

11.Are there any color consistency issues with smd led diode?

12.What are the benefits of using smd led diode technology?

13.Is smd led diode suitable for use in humid or wet environments?

14.Can smd led diode be used in hazardous locations?

15.What is the color rendering index (CRI) of smd led diode?

1.How does smd led diode handle voltage fluctuations?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

SMD LED (Surface Mount Device LED) is designed to handle voltage fluctuations by using a constant current driver. This driver regulates the current flowing through the LED, ensuring that the LED receives a consistent amount of power regardless of the voltage fluctuations. This helps to protect the LED from damage and maintain its brightness and lifespan. Additionally, SMD LEDs are also designed with built-in resistors that help to stabilize the voltage and prevent any sudden spikes or drops that could damage the LED.

2.Are smd led diodes energy efficient?

We pay attention to the transformation of intellectual property protection and innovation achievements. Your OEM or ODM order design we have a complete confidentiality system.

Yes, SMD LEDs (Surface Mount Device Light Emitting Diodes) are energy efficient. They use significantly less energy than traditional incandescent or fluorescent bulbs, making them a popular choice for energy-conscious consumers. SMD LEDs also have a longer lifespan, further contributing to their energy efficiency.

3.How does the color temperature of smd led diode affect its use?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

The color temperature of SMD LED affects its use in several ways:

1. Color appearance: The color temperature of an SMD LED determines the color appearance of the light it emits. A lower color temperature (2700K-3000K) produces warm white light, while a higher color temperature (5000K-6500K) produces cool white light. This can affect the ambiance and mood of a space, as well as the visibility and clarity of objects under the light.

2. Application suitability: The color temperature of an SMD LED can make it more suitable for certain applications. For example, warm white light is often preferred for residential and hospitality settings, while cool white light is more suitable for commercial and industrial settings.

3. Color rendering: The color temperature of an SMD LED can also affect its color rendering index (CRI), which is a measure of how accurately the light source renders colors compared to natural light. A higher color temperature can result in a higher CRI, making colors appear more vibrant and true to life.

4. Energy efficiency: The color temperature of an SMD LED can also impact its energy efficiency. Generally, higher color temperatures require more energy to produce, so a lower color temperature may be more energy-efficient.

5. Human health: The color temperature of an SMD LED can also have an impact on human health. Exposure to cool white light with a high color temperature at night can disrupt the body's natural sleep-wake cycle, while warm white light with a lower color temperature is less likely to have this effect.

Overall, the color temperature of an SMD LED is an important factor to consider when choosing the right lighting for a specific application, as it can affect the appearance, suitability, energy efficiency, and potential health impacts of the light.

4.What is the typical power consumption of smd led diode?

smd led diode is not a product only, but also can help you comes to money-making.

The typical power consumption of SMD LED varies depending on the size and type of the LED. Generally, the power consumption can range from 0.05 watts to 1 watt per LED. However, some high-power SMD LEDs can consume up to 5 watts. It is important to check the specifications of the specific SMD LED to determine its power consumption.

5.What is the installation process for smd led diode?

Our mission is to provide customers with the best solutions for smd led diode.

1. Gather Materials: Before starting the installation process, make sure you have all the necessary materials including the SMD LED lights, power supply, soldering iron, solder, wire strippers, and heat shrink tubing.

2. Plan the Layout: Decide on the placement of the SMD LED lights and plan the wiring layout accordingly. Make sure to measure the distance between each light and the power supply to determine the length of wire needed.

3. Prepare the Surface: Clean the surface where the SMD LED lights will be installed to ensure a strong and secure bond. If the surface is rough, use sandpaper to smooth it out.

4. Solder the Wires: Strip the ends of the wires and solder them to the positive and negative terminals of the SMD LED lights. Make sure to match the polarity of the wires to the correct terminals on the lights.

5. Connect the Lights: Once all the wires are soldered, connect them to the power supply. The positive wire should be connected to the positive terminal and the negative wire to the negative terminal.

6. Secure the Wires: Use heat shrink tubing to cover the soldered connections and secure them in place. This will prevent any short circuits and ensure a clean and professional look.

7. Test the Lights: Before permanently installing the lights, test them to make sure they are working properly. If there are any issues, double check the connections and fix any problems before proceeding.

8. Install the Lights: Once the lights are tested and working, use adhesive tape or glue to secure them in place. Make sure to follow the manufacturer's instructions for the best adhesive to use for your specific surface.

9. Connect to Power: Plug the power supply into a wall outlet and turn on the lights to make sure they are working correctly.

10. Clean Up: Once the installation is complete, clean up any excess wires and materials. Enjoy your newly installed SMD LED lights!

6.About smd led diode quality system

Our factory operates on an ERP system, which allows for efficient management and coordination of our operations. In addition, we are proud to have obtained ISO9001 certification, demonstrating our commitment to quality and customer satisfaction.

7.How does smd led diode hold up against extreme weather conditions?

We have established a good reputation and reliable partnerships within the smd led diode industry.

SMD LED (Surface Mount Device Light Emitting Diode) is designed to be more durable and resistant to extreme weather conditions compared to traditional LED lights. This is due to its compact size and construction, which allows it to withstand harsh environments and temperature fluctuations.

SMD LED lights are typically sealed with a silicone or epoxy resin, making them waterproof and dustproof. This protects the internal components from moisture, humidity, and other environmental factors that can cause damage to the LED.

In terms of extreme temperatures, SMD LED lights can operate in a wide range, from -40°C to 85°C. This makes them suitable for use in both hot and cold climates. They are also designed to withstand thermal shock, which is the sudden change in temperature that can cause damage to other types of LED lights.

Furthermore, SMD LED lights have a longer lifespan compared to traditional LED lights, making them more reliable in extreme weather conditions. They also have a lower failure rate and require less maintenance, making them a cost-effective option for outdoor and industrial applications.

Overall, SMD LED lights are highly durable and can hold up well against extreme weather conditions, making them a popular choice for outdoor and industrial lighting. However, it is always important to choose high-quality SMD LED lights from reputable manufacturers to ensure their performance and durability.

8.What is the warranty period for smd led diode?

We actively participate in the smd led diode industry associations and organization activities. The corporate social responsibility performed well, and the focus of brand building and promotion The warranty period for SMD LED varies depending on the manufacturer and the specific product. Generally, the warranty period can range from 1 to 5 years. It is important to check with the manufacturer or retailer for the specific warranty period for the SMD LED product you are interested in purchasing.

9.Are there any environmental considerations when using smd led diode?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers.

Yes, there are several environmental considerations when using SMD LED:

1. Energy Efficiency: SMD LED lights are highly energy-efficient, consuming less electricity compared to traditional incandescent or fluorescent lights. This reduces the overall energy consumption and helps in reducing carbon emissions.

2. Toxic Materials: Some SMD LED lights contain toxic materials such as lead, mercury, and arsenic, which can be harmful to the environment if not disposed of properly. It is important to recycle these lights properly to prevent these toxic materials from entering the environment.

3. E-waste: SMD LED lights are electronic devices and can contribute to the growing problem of e-waste. It is important to dispose of them properly to prevent them from ending up in landfills and polluting the environment.

4. Light Pollution: SMD LED lights can contribute to light pollution, which can disrupt the natural cycles of plants and animals and affect their behavior. It is important to use SMD LED lights responsibly and avoid unnecessary lighting to reduce light pollution.

5. Manufacturing Process: The manufacturing process of SMD LED lights can also have an impact on the environment. It requires a significant amount of energy and resources, and the disposal of waste materials can also be a concern. Choosing SMD LED lights from manufacturers with sustainable and environmentally friendly practices can help reduce the environmental impact.

6. End-of-life Disposal: When SMD LED lights reach the end of their lifespan, they need to be disposed of properly. If not recycled or disposed of correctly, they can release toxic materials into the environment. It is important to follow proper disposal guidelines and recycle SMD LED lights to reduce their environmental impact.

10.About the scale of smd led diode factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

11.Are there any color consistency issues with smd led diode?

We have a first -class management team, and we pay attention to teamwork to achieve common goals.

Yes, there can be color consistency issues with SMD LED. This can be due to variations in the manufacturing process, differences in the materials used, and variations in the color temperature of the LED chips. Additionally, factors such as temperature, aging, and voltage can also affect the color consistency of SMD LED. To ensure color consistency, it is important to source SMD LED from reputable manufacturers and to use LED drivers that provide stable voltage and current.

12.What are the benefits of using smd led diode technology?

We maintain a stable growth through reasonable capital operations, focus on industry development trends and cutting -edge technologies, and focus on product quality and safety performance.

1. Energy Efficiency: SMD LEDs are highly energy-efficient, consuming up to 80% less energy than traditional incandescent bulbs. This makes them a cost-effective option for lighting.

2. Long Lifespan: SMD LEDs have a longer lifespan compared to traditional bulbs, lasting up to 50,000 hours or more. This means they require less frequent replacements, reducing maintenance costs.

3. Compact Size: SMD LEDs are small in size, making them ideal for use in compact electronic devices such as smartphones, laptops, and TVs. They also allow for more flexibility in design and can be used in a variety of applications.

4. Brightness: SMD LEDs produce bright and uniform light, making them suitable for use in a wide range of lighting applications, from task lighting to ambient lighting.

5. Low Heat Emission: SMD LEDs emit very little heat, making them safe to use in close proximity to heat-sensitive materials or in confined spaces.

6. Durability: SMD LEDs are more durable than traditional bulbs as they are not made of fragile materials like glass. They are also resistant to shock and vibrations, making them suitable for use in rugged environments.

7. Instant On: SMD LEDs light up instantly without any warm-up time, unlike traditional bulbs that take a few seconds to reach full brightness.

13.Is smd led diode suitable for use in humid or wet environments?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process.

Yes, SMD LED (Surface Mount Device LED) is suitable for use in humid or wet environments. SMD LEDs are designed to be more durable and resistant to moisture compared to traditional through-hole LEDs. They have a protective coating that helps to prevent water and moisture from damaging the LED components. However, it is important to note that SMD LEDs are not completely waterproof and may still be damaged if submerged in water for extended periods of time. It is always recommended to check the IP (Ingress Protection) rating of the SMD LED before using it in a humid or wet environment to ensure it is suitable for the specific conditions.

14.Can smd led diode be used in hazardous locations?

We enjoy high authority and influence in the industry and continue to innovate products and service models.

No, SMD LED cannot be used in hazardous locations as they are not designed to withstand the potential risks and dangers present in these environments. Hazardous locations are defined as areas where flammable gases, vapors, or dusts may be present, and SMD LED may not have the necessary certifications or protections to operate safely in these conditions. It is important to use LED lighting specifically designed and certified for hazardous locations in these environments to ensure safety and compliance with regulations.

15.What is the color rendering index (CRI) of smd led diode?

Our smd led diode products have competitive and differentiated advantages, and actively promote digital transformation and innovation. The color rendering index (CRI) of SMD LED can vary depending on the specific type and brand, but generally ranges from 70 to 90. Some high-quality SMD LEDs may have a CRI of 95 or higher.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China