smd led bar

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

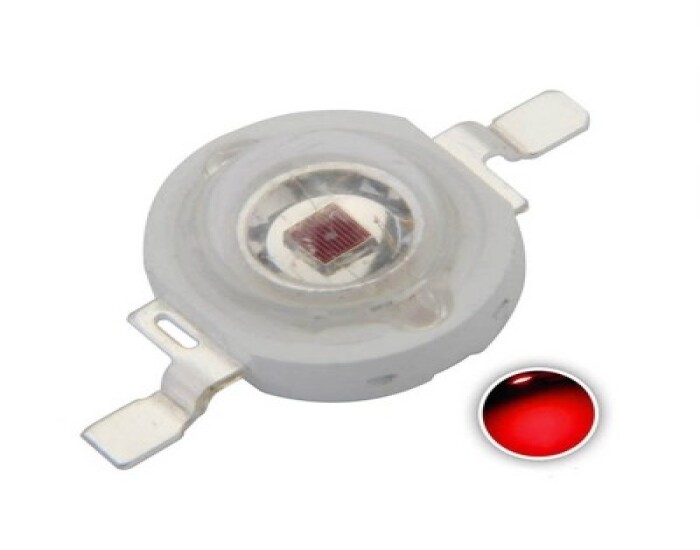

| Product name | smd led bar |

| Keyword | ac 5050 smd led strip lights,3528 smd led strip connector usb,g9 35 smd led light bulb,6 smd led festoon,8v smd led strip,china smd led flexible strips supplier,5050 smd led especificaciones,3020 smd led lumens |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 114MA |

| Power | 1.9W |

| Voltage | 0.8V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2832pcs/reel |

| Dimensions | 4.5mm*5.2mm*1.4mm, (Contact us for specific information to confirm) |

| Applicable Industries | road traffic, etc. |

| Color | red |

| Weight | 7mg |

| Product Description | 5 mm smd led strip,0402 smd led,400 nm smd led,SMD 5050 LED 1.5W RGB chip-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 53810 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 13x11.18x11mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Pakistan,Marshall Islands,Guinea,Turkmenistan,Guernsey |

| MOQ | 3 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 89kk pieces of LEDs per month. |

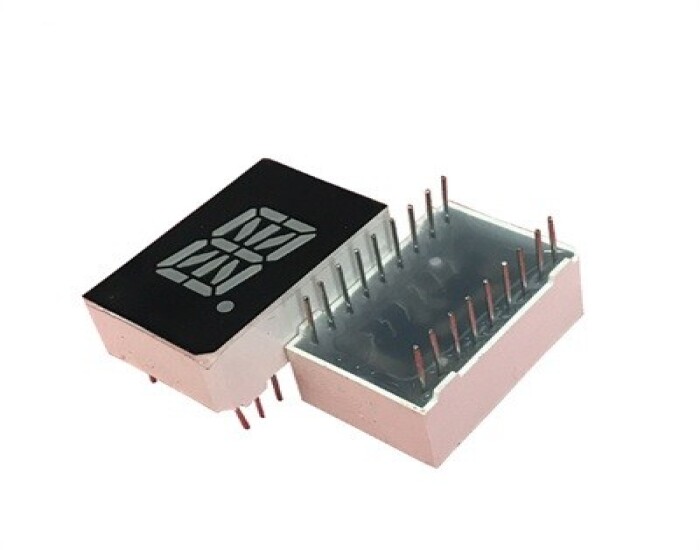

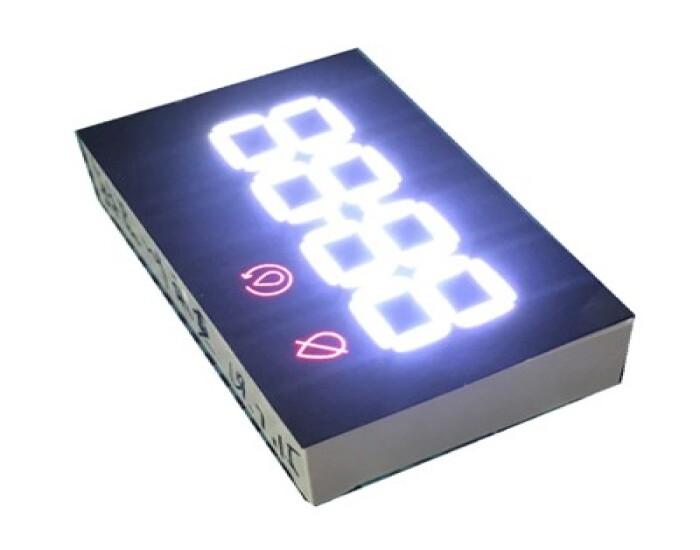

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

smd led bar services FAQs Guide

Are you looking for a quick review guide about smd led barservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding smd led bar services.

Let’s continue!

2.About smd led bar production equipment

3.What is the viewing angle of smd led bar?

4.Are there any regulations or certifications for smd led bar?

5.Can smd led bar be used for signage or display lighting?

6.How does smd led bar handle heat dissipation?

7.Are there any color options available for smd led bar?

8.What is the lifespan of an smd led bar?

9.About the scale of smd led bar factory

1.What is the installation process for smd led bar?

Our mission is to provide customers with the best solutions for smd led bar.

1. Gather Materials: Before starting the installation process, make sure you have all the necessary materials including the SMD LED lights, power supply, soldering iron, solder, wire strippers, and heat shrink tubing.

2. Plan the Layout: Decide on the placement of the SMD LED lights and plan the wiring layout accordingly. Make sure to measure the distance between each light and the power supply to determine the length of wire needed.

3. Prepare the Surface: Clean the surface where the SMD LED lights will be installed to ensure a strong and secure bond. If the surface is rough, use sandpaper to smooth it out.

4. Solder the Wires: Strip the ends of the wires and solder them to the positive and negative terminals of the SMD LED lights. Make sure to match the polarity of the wires to the correct terminals on the lights.

5. Connect the Lights: Once all the wires are soldered, connect them to the power supply. The positive wire should be connected to the positive terminal and the negative wire to the negative terminal.

6. Secure the Wires: Use heat shrink tubing to cover the soldered connections and secure them in place. This will prevent any short circuits and ensure a clean and professional look.

7. Test the Lights: Before permanently installing the lights, test them to make sure they are working properly. If there are any issues, double check the connections and fix any problems before proceeding.

8. Install the Lights: Once the lights are tested and working, use adhesive tape or glue to secure them in place. Make sure to follow the manufacturer's instructions for the best adhesive to use for your specific surface.

9. Connect to Power: Plug the power supply into a wall outlet and turn on the lights to make sure they are working correctly.

10. Clean Up: Once the installation is complete, clean up any excess wires and materials. Enjoy your newly installed SMD LED lights!

2.About smd led bar production equipment

Our factory comprises three production departments, housing a total of 12 production lines. We have equipped these lines with over 120 automatic machines from renowned brands such as ASM and Kaijo.

3.What is the viewing angle of smd led bar?

We are a new smd led bar manufacturer.

The viewing angle of SMD LED can vary depending on the specific model and manufacturer, but it is typically between 120-180 degrees. This means that the light emitted from the LED can be seen from a wide angle, making it suitable for use in applications where a broad and even distribution of light is desired.

4.Are there any regulations or certifications for smd led bar?

We continue to invest in research and development and continue to launch innovative products.

Yes, there are several regulations and certifications for SMD LED (Surface Mount Device Light Emitting Diode) products. These include:

1. RoHS (Restriction of Hazardous Substances) Directive: This regulation restricts the use of certain hazardous substances in electrical and electronic equipment, including SMD LED products.

2. CE (Conformité Européenne) Marking: This is a mandatory conformity marking for products sold in the European Economic Area (EEA) and indicates that the product meets all applicable EU directives, including those related to safety, health, and environmental protection.

3. UL (Underwriters Laboratories) Certification: UL is a global safety certification company that tests and certifies products for compliance with safety standards. SMD LED products can be UL certified to ensure their safety and quality.

4. Energy Star Certification: This is a voluntary program run by the U.S. Environmental Protection Agency (EPA) that certifies energy-efficient products, including SMD LED lighting products.

5. ISO (International Organization for Standardization) Standards: ISO has developed several standards related to LED lighting, including ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 50001 (energy management).

6. Ingress Protection (IP) Rating: This is a standard that rates the level of protection provided by a product against solid objects and liquids. SMD LED products may have an IP rating to indicate their resistance to dust and water.

7. LM-80 and TM-21 Standards: These are industry standards for measuring the lumen maintenance and projected lifetime of LED products, respectively.

It is important to note that not all SMD LED products may have all of these certifications or comply with all regulations. It is recommended to check the product specifications and certifications before purchasing to ensure compliance with relevant standards.

5.Can smd led bar be used for signage or display lighting?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

Yes, SMD (Surface Mount Device) LED can be used for signage and display lighting. SMD LED is a type of LED that is mounted directly onto a circuit board, making it smaller and more compact than traditional through-hole LEDs. This makes it a popular choice for applications where space is limited, such as signage and display lighting.

SMD LED also offers a wide range of color options, high brightness, and energy efficiency, making it suitable for creating eye-catching and vibrant displays. Additionally, SMD LED can be easily controlled and programmed to create dynamic lighting effects, making it a versatile choice for signage and display lighting.

6.How does smd led bar handle heat dissipation?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced smd led bar products.

SMD (Surface Mount Device) LED chips are designed to handle heat dissipation in several ways:

1. Heat Sink: SMD LEDs are often mounted on a heat sink, which is a metal plate or structure that helps to dissipate heat away from the LED chip. The heat sink provides a larger surface area for heat to dissipate, allowing the LED to operate at a lower temperature.

2. Thermal Pad: Some SMD LEDs have a thermal pad on the bottom of the chip, which helps to transfer heat away from the LED and onto the heat sink.

3. Thermal Via: SMD LEDs may also have thermal vias, which are small holes in the PCB (printed circuit board) that allow heat to transfer from the LED chip to the other side of the board, where it can be dissipated.

4. Copper Traces: The PCB may also have copper traces that act as heat sinks, helping to dissipate heat away from the LED chip.

5. Encapsulation: SMD LEDs are often encapsulated in a material that helps to dissipate heat, such as silicone or epoxy. This material also protects the LED chip from external factors that could affect its performance.

Overall, SMD LEDs are designed to efficiently dissipate heat and maintain a low operating temperature, which helps to prolong their lifespan and maintain their performance.

7.Are there any color options available for smd led bar?

We have advantages in marketing and channel expansion. Suppliers have established good cooperative relations, continuously improved workflows, improved efficiency and productivity, and provided customers with high -quality products and services.

Yes, there are many color options available for SMD LED. Some common colors include red, green, blue, yellow, white, and RGB (red, green, blue) combinations. Other colors such as pink, purple, orange, and amber are also available. Additionally, SMD LEDs can also be programmed to display a wide range of colors using RGB technology.

8.What is the lifespan of an smd led bar?

We have a professional team that is committed to the innovation and development of smd led bar.

The lifespan of an SMD LED can vary depending on the quality of the LED and its usage. On average, an SMD LED can last anywhere from 50,000 to 100,000 hours. This translates to approximately 5-10 years of continuous use. However, factors such as heat, voltage, and current can affect the lifespan of an SMD LED. Proper installation and maintenance can also help extend the lifespan of an SMD LED.

9.About the scale of smd led bar factory

Our factory covers an area of 12000㎡, including a 600㎡ 10k class dust-free, anti-static workshop.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China