flexible smd led light strip silicone sleeve

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | flexible smd led light strip silicone sleeve |

| Keyword | blinking smd led,2mm smd led,30w smd led chip,5050 smd led module supplier,2835 smd led chip,halo smd led,cob or smd led |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 82MA |

| Power | 1.4W |

| Voltage | 3.1V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2783pcs/reel |

| Dimensions | 4.4mm*4.5mm*1.8mm, (Contact us for specific information to confirm) |

| Applicable Industries | urban lighting, etc. |

| Color | green |

| Weight | 15mg |

| Product Description | SMD 5630 LED 0.5W Mixyellow chip,0.5w smd led 3v,4v smd led strip-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 50007 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 14x14.82x12.1mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Ukraine,Romania,Thailand,Bangladesh,Finland,Singapore,Serbia and Montenegro |

| MOQ | 6 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 97kk pieces of LEDs per month. |

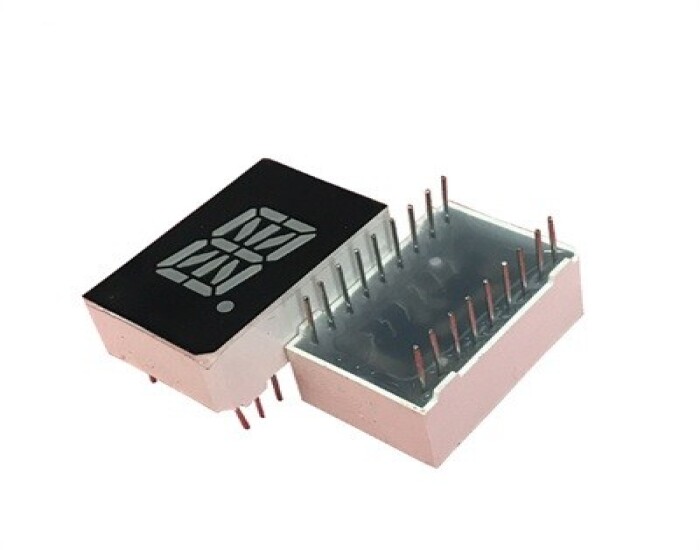

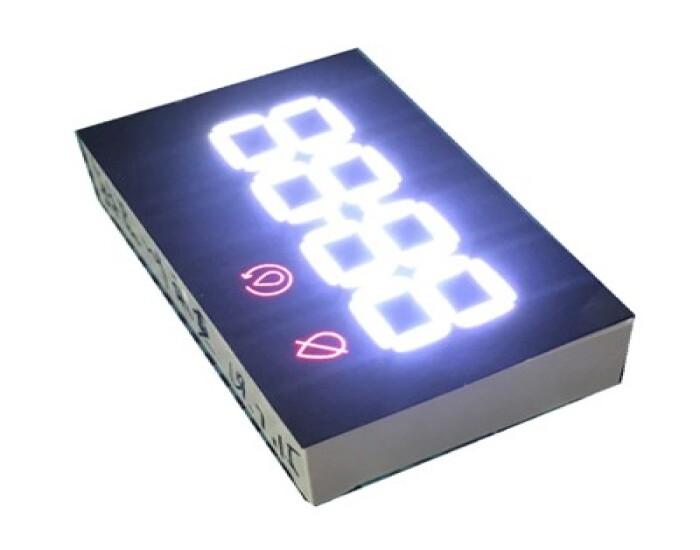

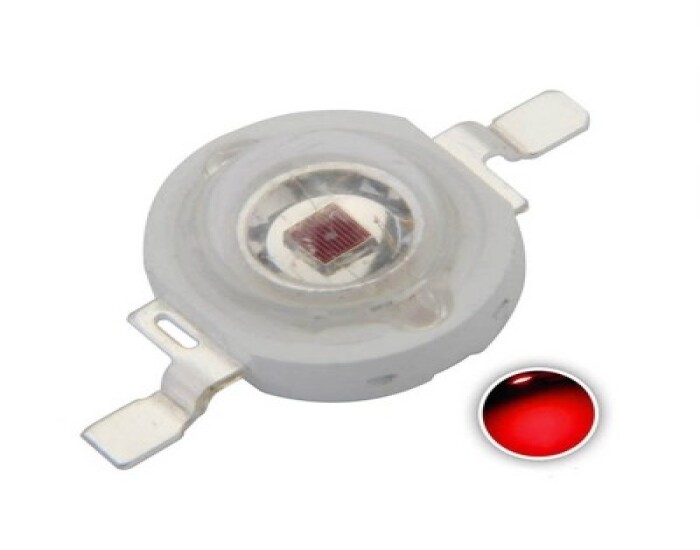

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

flexible smd led light strip silicone sleeve services FAQs Guide

Are you looking for a quick review guide about flexible smd led light strip silicone sleeveservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding flexible smd led light strip silicone sleeve services.

Let’s continue!

2.What is the installation process for flexible smd led light strip silicone sleeve?

3.How does flexible smd led light strip silicone sleeve handle heat dissipation?

4.About flexible smd led light strip silicone sleeve production management system

5.How does flexible smd led light strip silicone sleeve emit light compared to other types of LEDs?

6.How does flexible smd led light strip silicone sleeve handle glare and eye strain?

7.About flexible smd led light strip silicone sleeve production equipment

8.Can flexible smd led light strip silicone sleeve lights be dimmed?

1.About flexible smd led light strip silicone sleeve raw material procurement system

Our production process is closely monitored through an ERP system and MES system, ensuring the stability and traceability of our products.

2.What is the installation process for flexible smd led light strip silicone sleeve?

Our mission is to provide customers with the best solutions for flexible smd led light strip silicone sleeve.

1. Gather Materials: Before starting the installation process, make sure you have all the necessary materials including the SMD LED lights, power supply, soldering iron, solder, wire strippers, and heat shrink tubing.

2. Plan the Layout: Decide on the placement of the SMD LED lights and plan the wiring layout accordingly. Make sure to measure the distance between each light and the power supply to determine the length of wire needed.

3. Prepare the Surface: Clean the surface where the SMD LED lights will be installed to ensure a strong and secure bond. If the surface is rough, use sandpaper to smooth it out.

4. Solder the Wires: Strip the ends of the wires and solder them to the positive and negative terminals of the SMD LED lights. Make sure to match the polarity of the wires to the correct terminals on the lights.

5. Connect the Lights: Once all the wires are soldered, connect them to the power supply. The positive wire should be connected to the positive terminal and the negative wire to the negative terminal.

6. Secure the Wires: Use heat shrink tubing to cover the soldered connections and secure them in place. This will prevent any short circuits and ensure a clean and professional look.

7. Test the Lights: Before permanently installing the lights, test them to make sure they are working properly. If there are any issues, double check the connections and fix any problems before proceeding.

8. Install the Lights: Once the lights are tested and working, use adhesive tape or glue to secure them in place. Make sure to follow the manufacturer's instructions for the best adhesive to use for your specific surface.

9. Connect to Power: Plug the power supply into a wall outlet and turn on the lights to make sure they are working correctly.

10. Clean Up: Once the installation is complete, clean up any excess wires and materials. Enjoy your newly installed SMD LED lights!

3.How does flexible smd led light strip silicone sleeve handle heat dissipation?

We have advanced production equipment and technology to meet the needs of customers, and can provide customers with high quality, low priced flexible smd led light strip silicone sleeve products.

SMD (Surface Mount Device) LED chips are designed to handle heat dissipation in several ways:

1. Heat Sink: SMD LEDs are often mounted on a heat sink, which is a metal plate or structure that helps to dissipate heat away from the LED chip. The heat sink provides a larger surface area for heat to dissipate, allowing the LED to operate at a lower temperature.

2. Thermal Pad: Some SMD LEDs have a thermal pad on the bottom of the chip, which helps to transfer heat away from the LED and onto the heat sink.

3. Thermal Via: SMD LEDs may also have thermal vias, which are small holes in the PCB (printed circuit board) that allow heat to transfer from the LED chip to the other side of the board, where it can be dissipated.

4. Copper Traces: The PCB may also have copper traces that act as heat sinks, helping to dissipate heat away from the LED chip.

5. Encapsulation: SMD LEDs are often encapsulated in a material that helps to dissipate heat, such as silicone or epoxy. This material also protects the LED chip from external factors that could affect its performance.

Overall, SMD LEDs are designed to efficiently dissipate heat and maintain a low operating temperature, which helps to prolong their lifespan and maintain their performance.

4.About flexible smd led light strip silicone sleeve production management system

We have implemented a robust production management system that leverages our ERP system, specifically incorporating material information, BOM information, and supplier information. This system allows us to monitor equipment control and production stability in real-time through the MES system.

5.How does flexible smd led light strip silicone sleeve emit light compared to other types of LEDs?

Our company has many years of flexible smd led light strip silicone sleeve experience and expertise.

SMD (Surface Mount Device) LEDs emit light in a similar way to other types of LEDs, but they have a different construction and packaging that allows for more efficient and compact use.

Like other LEDs, SMD LEDs use a semiconductor material, typically gallium nitride (GaN), to produce light when an electric current is applied. The semiconductor is sandwiched between two layers of different materials, called the p-type and n-type layers. When a voltage is applied to the LED, electrons from the n-type layer flow into the p-type layer, where they combine with positively charged holes" to produce light.

6.How does flexible smd led light strip silicone sleeve handle glare and eye strain?

As one of the top flexible smd led light strip silicone sleeve manufacturers in China, we take this very seriously.

SMD LED (Surface Mount Device Light Emitting Diode) technology is designed to reduce glare and eye strain compared to traditional LED lighting. This is achieved through several factors:

1. Diffusion: SMD LEDs are designed with a diffused lens that helps to spread the light evenly, reducing the intensity of the light and minimizing glare.

2. Directionality: SMD LEDs emit light in a specific direction, unlike traditional LEDs which emit light in all directions. This directional light helps to reduce glare and direct the light where it is needed.

3. Color temperature: SMD LEDs have a color temperature that is closer to natural daylight, which is easier on the eyes compared to the harsh blue light emitted by traditional LEDs.

4. Flicker-free: SMD LEDs are designed to be flicker-free, meaning they do not produce rapid fluctuations in light intensity that can cause eye strain and headaches.

5. Dimmability: SMD LEDs can be dimmed, allowing for customizable lighting levels that can be adjusted to reduce glare and eye strain.

Overall, SMD LED technology is designed to provide a more comfortable and natural lighting experience, reducing glare and eye strain for the user.

7.About flexible smd led light strip silicone sleeve production equipment

Our factory comprises three production departments, housing a total of 12 production lines. We have equipped these lines with over 120 automatic machines from renowned brands such as ASM and Kaijo.

8.Can flexible smd led light strip silicone sleeve lights be dimmed?

Being one of the top flexible smd led light strip silicone sleeve manufacturers in China, We attach great importance to this detail.

Yes, SMD LED lights can be dimmed. However, not all SMD LED lights are dimmable, so it is important to check the product specifications before attempting to dim them. Additionally, the type of dimmer used must be compatible with the SMD LED lights.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China