0603 smd led soldering

- Category: 2016 SMD LED

- Brand:ARKTECH

- delivery date: 7 to 9 working days

- payment method: We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit)

- Our team offers all-round technical support, including designing according to your requirements, selecting the best solutions based on cost and reliability, principle and LAY-OUT design, customizing s

| Product name | 0603 smd led soldering |

| Keyword | flash high power smd led,2012 smd led,china smd led bulb supplier,smd led flexible strips 3528,4014 smd led lumens,amber oracle smd led turn signal tundra,5 watt smd led |

| Place of Origin | China |

| Brand | ARKTECH |

| Current | 89MA |

| Power | 0.9W |

| Voltage | 0.8V |

| Raw material | Copper bracket/ pure gold wire |

| Quantity | 2858pcs/reel |

| Dimensions | 5.3mm*5.4mm*1.9mm, (Contact us for specific information to confirm) |

| Applicable Industries | city lightening engineering, etc. |

| Color | Ash |

| Weight | 18mg |

| Product Description | SMD 5050 LED RGB+Warm white 0.2w chip,0.2 watt smd led,4 pin smd led,0403 smd led,SMD 5050 LED Black surface RGB chip-It is a new surface packaging technology that encapsulates LED chips in tiny weldable packaging films and performs surface spot welding on the PCB substrate, thus improving the reliability and production efficiency of LEDs. Compared with traditional LED packaging, SMD LED has the advantages of small size, large light-emitting area, high power, low packaging height, and multiple color temperatures, and can greatly reduce costs through automated production processes. |

| delivery date | Our standard delivery time is 7 to 9 working days. |

| payment method | We offer payment options such as Paypal, TT (Telegraphic Transfer), or LC (Letter of Credit). |

| Life span | 52074 + hours (Contact us for specific information to confirm) |

| warranty | We provide a warranty period of 2 years |

| Advantage | We keep good quality and competitive price to ensure our customers benefit |

| Packing | 13x10.85x14mm(Contact us for specific information to confirm) |

| Sales country | All over the world for example:Panama,Pakistan,Pitcairn Islands,Kyrgyzstan,Navassa Island,Saint Kitts and Nevis |

| MOQ | 6 reel(Contact us for specific information to confirm) |

| customization services | We welcome customization requests for our products |

| production capacity | We have the capacity to produce 99kk pieces of LEDs per month. |

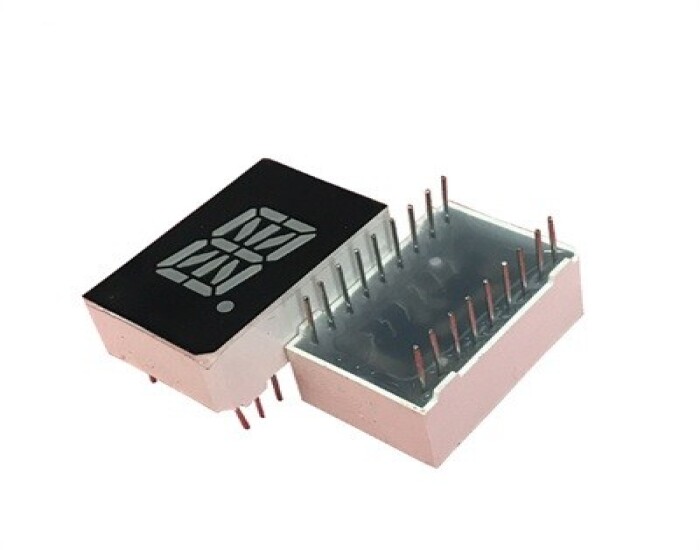

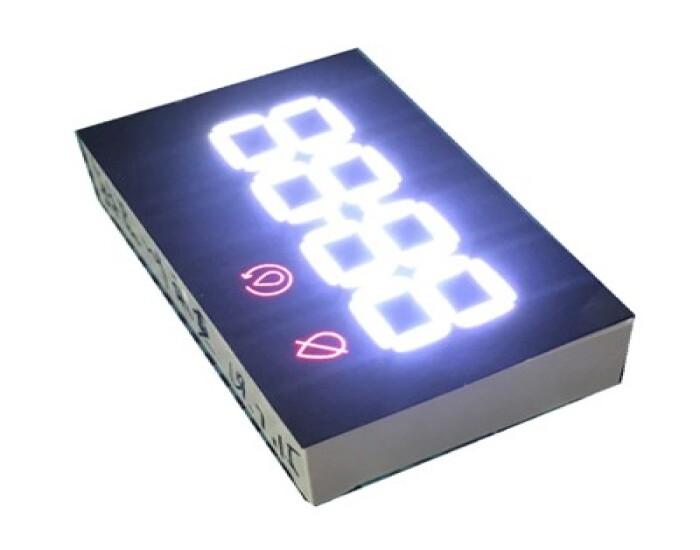

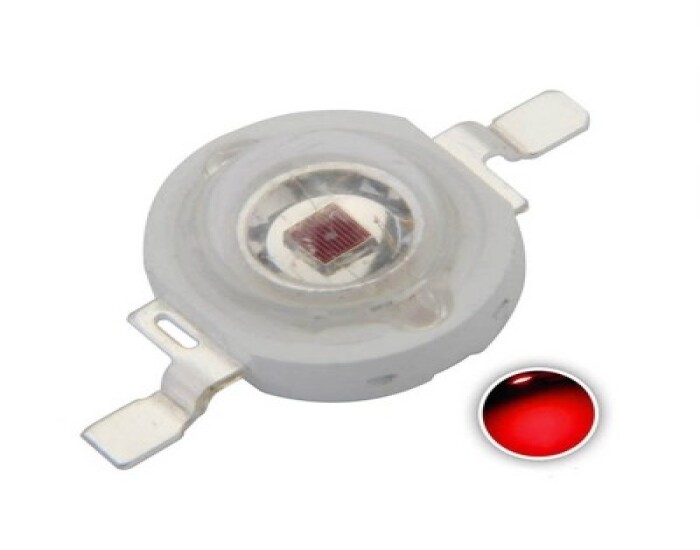

Segment led display, Custom LED display, Through hole LED, High power LED(Please contact us for specific information about Segment led display)

0603 smd led soldering services FAQs Guide

Are you looking for a quick review guide about 0603 smd led solderingservices?

An ultimate FAQ buying guide is available to help you.This guide contains all the information about all the important facts, figures, and various processes regarding 0603 smd led soldering services.

Let’s continue!

2.Are there any size limitations for 0603 smd led soldering?

3.About 0603 smd led soldering production skills training

4.Can 0603 smd led soldering be used for signage or display lighting?

5.Are there any regulations or certifications for 0603 smd led soldering?

6.What is the difference between 0603 smd led soldering and COB LED?

7.How does the color temperature of 0603 smd led soldering affect its use?

8.How does 0603 smd led soldering handle voltage fluctuations?

9.How does the cost of 0603 smd led soldering compare to other types of lighting?

10.How does the size of 0603 smd led soldering affect its performance?

1.What are 0603 smd led soldering lights?

Our 0603 smd led soldering products undergo strict quality control to ensure customer satisfaction.

SMD LED lights are a type of LED (light-emitting diode) light that uses surface-mount technology (SMT) to mount the LED chips onto a circuit board. This allows for a more compact and efficient design, as well as a wider range of color options. SMD LED lights are commonly used in electronic devices, automotive lighting, and general lighting applications. They are known for their energy efficiency, long lifespan, and low heat emission.

2.Are there any size limitations for 0603 smd led soldering?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail.

There are no specific size limitations for SMD LED, as they can be manufactured in various sizes and shapes to suit different applications. However, the smaller the size of the LED, the more challenging it is to manufacture and handle, which can affect its performance and reliability. Generally, SMD LEDs range from 0.2mm to 5mm in size.

3.About 0603 smd led soldering production skills training

We require all our employees to undergo three months of training. Only after successfully passing a qualified test are they allowed to work on the production line. To further ensure the quality of our goods, we have implemented diagrams along the production line, providing clear instructions and guidelines. Additionally, our HD engineers conduct monthly training sessions to keep our team updated with the latest production techniques and practices.

4.Can 0603 smd led soldering be used for signage or display lighting?

We have flexible production capacity. Whether you are large orders or small orders, you can produce and release goods in a timely manner to meet customer needs.

Yes, SMD (Surface Mount Device) LED can be used for signage and display lighting. SMD LED is a type of LED that is mounted directly onto a circuit board, making it smaller and more compact than traditional through-hole LEDs. This makes it a popular choice for applications where space is limited, such as signage and display lighting.

SMD LED also offers a wide range of color options, high brightness, and energy efficiency, making it suitable for creating eye-catching and vibrant displays. Additionally, SMD LED can be easily controlled and programmed to create dynamic lighting effects, making it a versatile choice for signage and display lighting.

5.Are there any regulations or certifications for 0603 smd led soldering?

We continue to invest in research and development and continue to launch innovative products.

Yes, there are several regulations and certifications for SMD LED (Surface Mount Device Light Emitting Diode) products. These include:

1. RoHS (Restriction of Hazardous Substances) Directive: This regulation restricts the use of certain hazardous substances in electrical and electronic equipment, including SMD LED products.

2. CE (Conformité Européenne) Marking: This is a mandatory conformity marking for products sold in the European Economic Area (EEA) and indicates that the product meets all applicable EU directives, including those related to safety, health, and environmental protection.

3. UL (Underwriters Laboratories) Certification: UL is a global safety certification company that tests and certifies products for compliance with safety standards. SMD LED products can be UL certified to ensure their safety and quality.

4. Energy Star Certification: This is a voluntary program run by the U.S. Environmental Protection Agency (EPA) that certifies energy-efficient products, including SMD LED lighting products.

5. ISO (International Organization for Standardization) Standards: ISO has developed several standards related to LED lighting, including ISO 9001 (quality management), ISO 14001 (environmental management), and ISO 50001 (energy management).

6. Ingress Protection (IP) Rating: This is a standard that rates the level of protection provided by a product against solid objects and liquids. SMD LED products may have an IP rating to indicate their resistance to dust and water.

7. LM-80 and TM-21 Standards: These are industry standards for measuring the lumen maintenance and projected lifetime of LED products, respectively.

It is important to note that not all SMD LED products may have all of these certifications or comply with all regulations. It is recommended to check the product specifications and certifications before purchasing to ensure compliance with relevant standards.

6.What is the difference between 0603 smd led soldering and COB LED?

We have rich industry experience and professional knowledge, and have strong competitiveness in the market.

SMD LED (Surface Mount Device LED) and COB LED (Chip on Board LED) are two different types of LED technology used in lighting applications. The main differences between them are:

1. Design: SMD LEDs are small, individual LED chips mounted on a circuit board, while COB LEDs consist of multiple LED chips bonded directly to a substrate, creating a single module.

2. Size: SMD LEDs are smaller in size compared to COB LEDs, making them suitable for compact and slim lighting designs.

3. Light output: COB LEDs have a higher light output compared to SMD LEDs due to their larger size and higher number of LED chips.

4. Heat dissipation: COB LEDs have better heat dissipation capabilities compared to SMD LEDs, as the multiple LED chips are spread out over a larger surface area.

5. Color consistency: COB LEDs have better color consistency compared to SMD LEDs, as the multiple LED chips are closely packed together, resulting in a more uniform color output.

6. Cost: SMD LEDs are generally less expensive compared to COB LEDs, making them a more cost-effective option for lighting applications.

In summary, SMD LEDs are smaller, more affordable, and suitable for compact designs, while COB LEDs have a higher light output, better heat dissipation, and color consistency. The choice between the two will depend on the specific lighting needs and budget of the application.

7.How does the color temperature of 0603 smd led soldering affect its use?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance.

The color temperature of SMD LED affects its use in several ways:

1. Color appearance: The color temperature of an SMD LED determines the color appearance of the light it emits. A lower color temperature (2700K-3000K) produces warm white light, while a higher color temperature (5000K-6500K) produces cool white light. This can affect the ambiance and mood of a space, as well as the visibility and clarity of objects under the light.

2. Application suitability: The color temperature of an SMD LED can make it more suitable for certain applications. For example, warm white light is often preferred for residential and hospitality settings, while cool white light is more suitable for commercial and industrial settings.

3. Color rendering: The color temperature of an SMD LED can also affect its color rendering index (CRI), which is a measure of how accurately the light source renders colors compared to natural light. A higher color temperature can result in a higher CRI, making colors appear more vibrant and true to life.

4. Energy efficiency: The color temperature of an SMD LED can also impact its energy efficiency. Generally, higher color temperatures require more energy to produce, so a lower color temperature may be more energy-efficient.

5. Human health: The color temperature of an SMD LED can also have an impact on human health. Exposure to cool white light with a high color temperature at night can disrupt the body's natural sleep-wake cycle, while warm white light with a lower color temperature is less likely to have this effect.

Overall, the color temperature of an SMD LED is an important factor to consider when choosing the right lighting for a specific application, as it can affect the appearance, suitability, energy efficiency, and potential health impacts of the light.

8.How does 0603 smd led soldering handle voltage fluctuations?

We are committed to providing personalized solutions and established long -term strategic cooperative relationships with customers.

SMD LED (Surface Mount Device LED) is designed to handle voltage fluctuations by using a constant current driver. This driver regulates the current flowing through the LED, ensuring that the LED receives a consistent amount of power regardless of the voltage fluctuations. This helps to protect the LED from damage and maintain its brightness and lifespan. Additionally, SMD LEDs are also designed with built-in resistors that help to stabilize the voltage and prevent any sudden spikes or drops that could damage the LED.

9.How does the cost of 0603 smd led soldering compare to other types of lighting?

We continuously upgrade our skills and knowledge to adapt to changing 0603 smd led soldering market needs.

The cost of SMD LED (Surface Mount Device Light Emitting Diode) is generally higher than other types of lighting such as incandescent, fluorescent, and halogen lights. This is because SMD LEDs are more energy-efficient, have a longer lifespan, and offer better color rendering compared to traditional lighting options.

However, the cost of SMD LED has decreased significantly in recent years due to advancements in technology and increased production. In some cases, the initial cost of purchasing SMD LED lights may be higher, but the long-term savings in energy and maintenance costs make them a more cost-effective option.

Additionally, the cost of SMD LED varies depending on the brand, quality, and features of the light. Higher-end SMD LED lights with advanced features such as dimming capabilities or smart controls may be more expensive than basic SMD LED lights.

Overall, while the initial cost of SMD LED may be higher, the long-term savings and benefits make them a more cost-effective and efficient lighting option.

10.How does the size of 0603 smd led soldering affect its performance?

We have broad development space in domestic and foreign markets. 0603 smd led soldering have great advantages in terms of price, quality, and delivery date.

The size of an SMD LED can affect its performance in several ways:

1. Brightness: Generally, larger SMD LEDs have a higher maximum brightness compared to smaller ones. This is because larger LEDs have more surface area to emit light, allowing them to produce a brighter output.

2. Power consumption: Smaller SMD LEDs typically have a lower power consumption compared to larger ones. This is because smaller LEDs require less energy to produce the same amount of light as larger ones.

3. Heat dissipation: Larger SMD LEDs tend to generate more heat compared to smaller ones. This is because they have a higher power consumption and more surface area to dissipate heat. This can affect the overall performance and lifespan of the LED.

4. Viewing angle: The size of an SMD LED can also affect its viewing angle, which is the angle at which the light is emitted from the LED. Smaller LEDs typically have a narrower viewing angle, while larger LEDs have a wider viewing angle.

5. Durability: Larger SMD LEDs are generally more durable and have a longer lifespan compared to smaller ones. This is because they have a larger surface area, which allows for better heat dissipation and reduces the risk of overheating and damage.

Overall, the size of an SMD LED can significantly impact its performance, and it is essential to consider the specific requirements and applications when choosing the appropriate size for a particular project.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Name: Ms.Wendy

Mobile:0086-15861679389

Tel:0086-81725657

Whatsapp:0086 17386542651

Email:info@arktechcn.com

Add:8# HengDa CaiFu Center, JinKai Industrial Area, Wuci City, Jiang Su, China